GENERAL INTRODUCTION

It is used for laminating thermoplastic such as foam materials through burning flame.

TECHNICAL DRAWING: ( reference only)

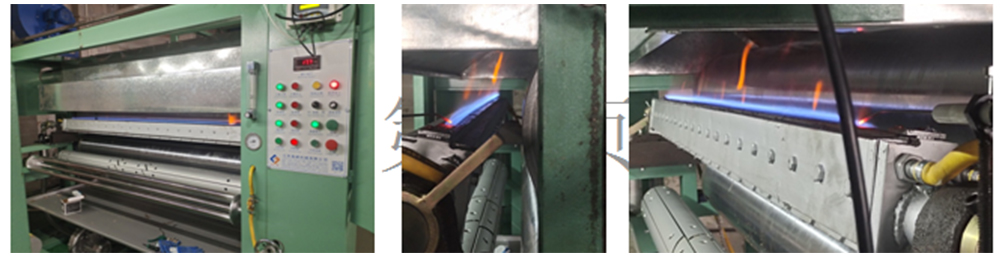

MACHINE PHOTO: (reference only)

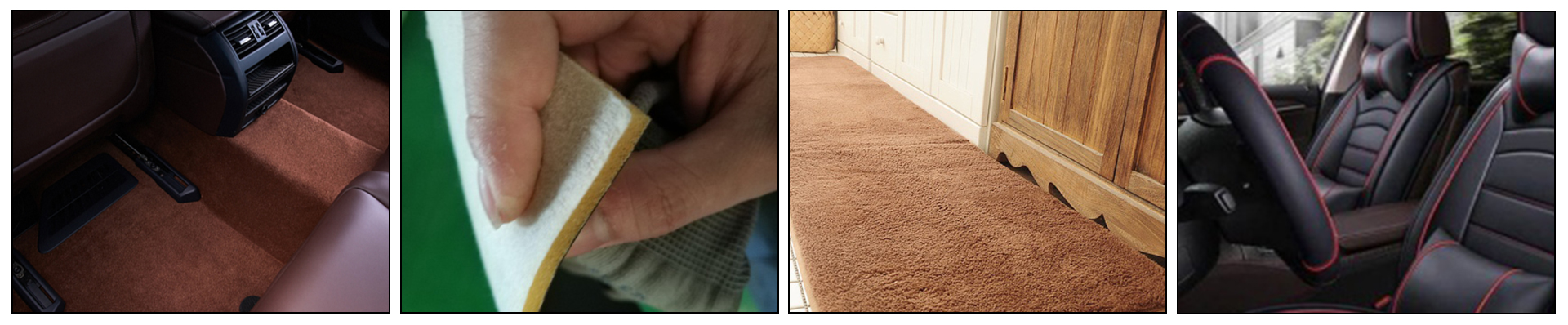

APPLICATION

Sponge is used to burn through flame jet to melt the surface and instantly bond with other textiles, non-woven products or artificial leather and other materials. The finished products are mostly used in industries such as carpets, clothing, toys, car interiors, sofa seat covers, decoration and packaging.

◆ Clothing,winter clothes,underwear

◆ Carpets,Mat,

◆ Car interiors,car seats

◆ Shoes,hats,bags

◆ Footwear

◆ Household cleaning products

◆ Heat insulation

APPLICATION PHOTO:

FEATURE

1. Gas Type: Natural Gas or Liquefied Gas.

2. The water cooling system well enhances the lamination effect.

3. The air exhaust diaphragm will exhaust the odor.

4. Fabric correction device is installed to make the laminated material smooth and neat.

5. The bonding strength depends on the material and the foam or EVA selected and the processing conditions.

6. With high integrity and long term adhesive durability, the laminated materials touch well and dry washable.

7. Edge sensor, constant tension for unwinding device, stamping ,jointing function and other auxiliary equipment can be optionally installed.

Main technical parameters

1). Manufacturing based on confirmed drawing

2). Effective width: 1900mm

3). Roll surface length: 2100mm

4). Working speed: 15-45m/min

5). Installed capacity: About 25KVA

6). Heat source: Natural Gas or Liquefied Gas

7). Combustion amount: 0.003-0.008KG/㎡

8). LWH: About 30380*3800*7000mm

9). Power supply: 380V 50HZ 3P /CUSTOMIZED

10). Operation control mode: PLC touch screen control