Full automatic eva hot melt spray coating laminating machine for shade cloth sofa cloth film curtain materials

It applied for gluing and laminating of hot melt glue onto textiles and nonwoven materials. The laminated products have the following advantages:

✦ Environmental

✦ Good adhesion

✦ Good flexibility

✦ Good thermal stability

✦ Smooth and flat

✦ Long lasting elasticity, wear resistance, oil resistance and oxidation resistance.

✦ Low maintenance cost and low operation noise.

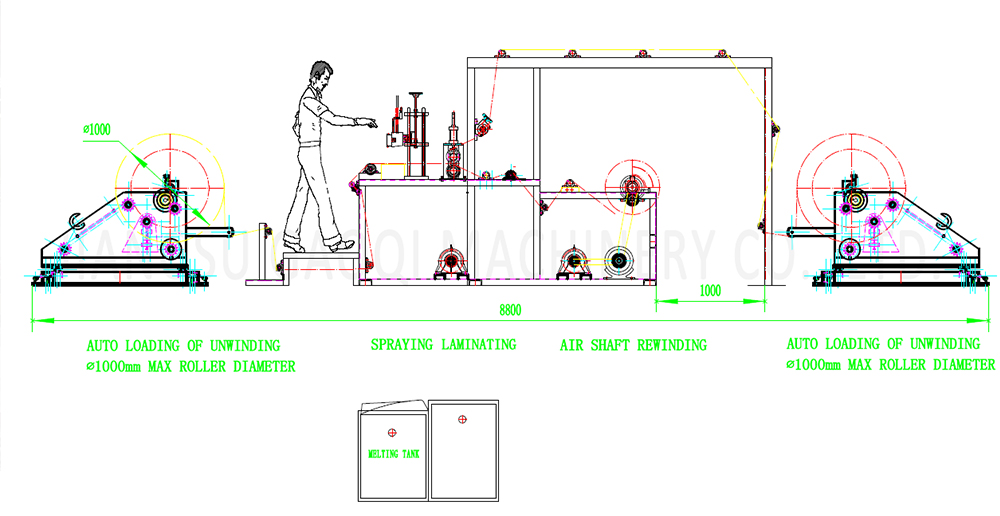

TECHNICAL DRAWING

TECHNICAL PARAMETERS

▷ Unwinding and rewinding diameter: 1000mm max

▷ Spray width: ≤ 1600mm.

▷ Paper tube length: 1600mm.

▷ Unwinding load: ≤500kg.

▷ Paper tube diameter: 76mm.

▷ Mechanical operating design speed: ≤ 50m/min

▷ Mechanical roller width: 1800mm

▷ Spray method: Full fiber spray, non-contact spray composite.

▷ Glue melting tank capacity:60kg

▷ Melting speed: 45kg/h

▷ Temperature control: Room temperature to 200 degrees c, pt100 temperature bar

▷ Air pressure source: 5 to 7kgf/cm2

▷ Unwinding tension: ≤50㎏

▷ Speed control: Variable frequency synchronous vehicle speed adjustment.

▷ Cooling method: Water cooling.

▷ Main frame: Steel plate and slot steel welding.

▷ Over size: About l9500mm x w2400mm x h2000mm

Application

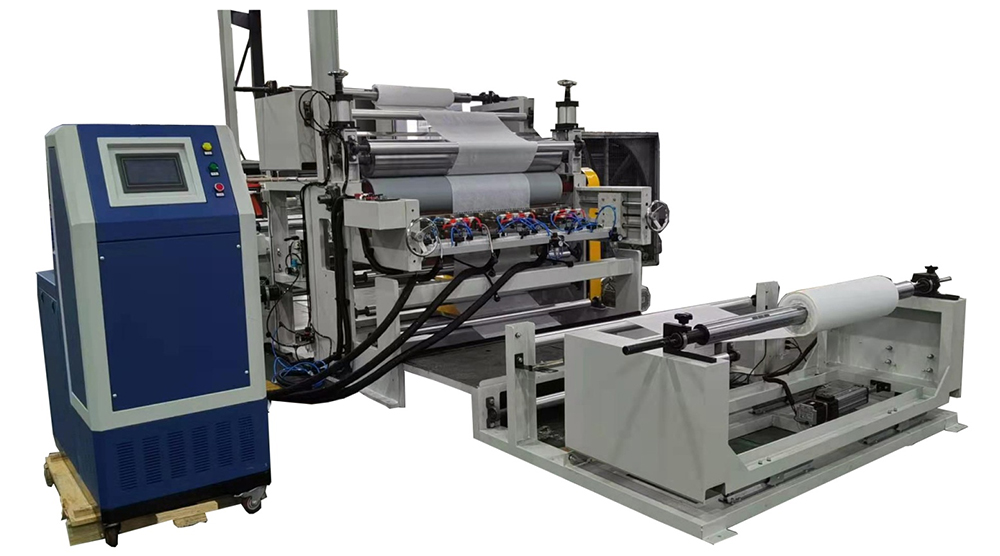

MACHINE PHOTO

(Reference only, final according to confirmed drawing)

INTRODUCTION

1. Suitable materials: non-woven, textile cloth, foam, sanitation and environmental protection non-glue powder materials.

2. PLC variable frequency control spray, according to the machine operating speed intelligent adjustment of the amount of spray, spray module consists of a number of nozzles, spray width can be set as needed, can produce different widths of materials, but also convenient for cleaning and maintenance of spray head.

3. Hot melt process, replace the traditional solvent-based glue, no need to heat and dry, production speed faster and smoother.

4. Unwinding equipped with magnetic powder stress control system and photoelectric correction system, to ensure accurate feeding.

5. Rewinding is equipped with friction shaft center rewinding system, to ensure the perfect rewinding.

6. The output meter function, accurately record the output.

7. Spray system contains air heating film, more suitable for high-temperature collosus spray. Working air pressure 5Mpa, jet pressure 1-2Mpa, spray using 5 pieces of multi-air control.

8. The cylinder by high temperature Teflon treatment, effectively prevent the carbonization of hot melt phenomenon. Double-layer heating is used to improve the melting speed and double-stage filtration after the pump before pump to ensure pure collage.

9. Combined with frequency inverter technology and microelectronics technology, PLC intelligent control of the amount of spray, spray accuracy ± 1 gram.

10. Main frame color: white or color selected by the customer.

WORKING PRINCIPLE