0 Water glue lamination machine

The machine uses white emulsion glue as adhesive and high-temperature resistant mesh belt to make it composite into a layer. At the same time, the mesh belt has the function of automatic deviation correction, so that the composite materials are neat, flat and free from deviation.

TECHNICAL DRAWING

TECHNICAL PARAMETERS

|

SPECIFICATION |

GQ-1500*1800 /CUSTOMIZED |

|

MAX. PRODUCTION WIDTH: |

1600mm /CUSTOMIZED |

|

ROLLER SURFACE WIDTH: |

1800mm /CUSTOMIZED |

|

VOLTAGE: |

380V 50HZ 3P /CUSTOMIZED |

|

HEATING DRUM SIZE: |

Ø1500*1800(CUSTOMIZED) |

|

OVERALL POWER: |

50kw |

|

HEATING MODE: |

Electric heating |

|

COATING METHOD: |

Roller coating |

|

DIMENSION(LXWXH) |

7000MMx3000MMx2650mm |

PRODUCT PHOTO

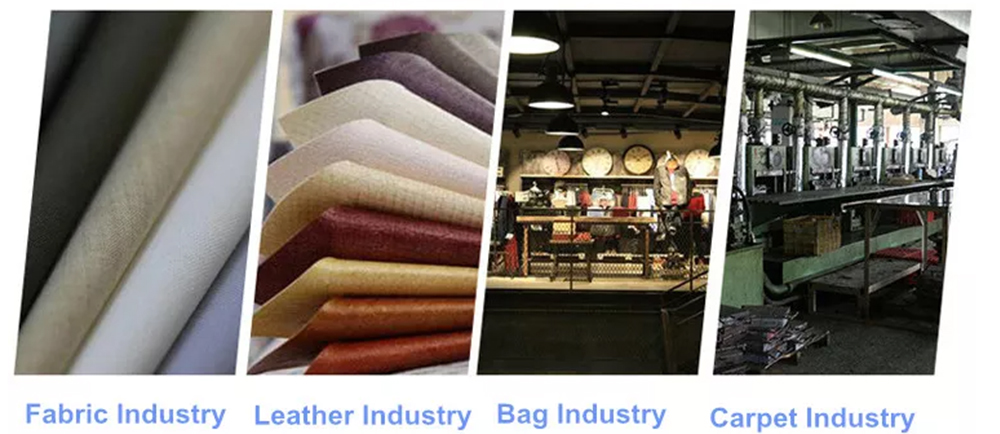

APPLICATION

The raw materials are cashmere, polar fleece, plush, suede, sponge, fabrics, non-woven fabrics, EVA, leather ,silk wadding and so on. The finished products are widely used for garment, shoes and hats, luggage, gloves, leather, automotive interiors, toys, carpet , home textiles , etc.

◇ Textile and garment industry

◇ Medical products industry

◇ Luggage industry

◇ Packaging industry

◇ Footwear industry

◇ Decoration industry

◇ Automotive interior industry

SUITABLE MATERIAL

✦ Fabric+Mesh, Fabric+Fabric,

✦ Polyfoam+Polyfoam

✦ Fabric+Sponge, Sanding Paper+Sponge

✦ Sponge+Mesh+Sponge

✦ Polar Fleece +Fabric

✦ Leather+Microfiber,Leather+Polyfoam

✦ Mesh+Film+Fabric

✦ Fabric+Film,Nonwoven fabric+Film

ADVANTAGE

◆ Low energy consumption and low cost

◆ Good drying effect

◆ Softness and washab;e

◆ Flat and Wrinkle free

◆ Good air permeability

FEATURE

◆ It uses water-based glue.

◆ Improve the quality of the products greatly, save cost.

◆ Vertical structure, low breakdown rate and long service time.

◆ Equipped with high quality heat resistance net belt to make the laminated materials contact closely with the drying cylinder, to improve the drying effect, and make the laminated product soft, washable, and strengthen adhesive fastness.

◆ This leather laminating machine has two sets of heating system, user can select one set heating mode or two sets, to reduce the energy consumption and lower costs.

◆ Surface of heating roller is coated with Teflon in order to efficacious prevent the hot melt adhesive against sticking on the surface of roller and carbonization.

◆ For clamp roller, both hand wheel adjustment and the pneumatic control are available.

◆ Equipped with automatic infrared centering control unit, which can effectively prevent the net belt deviation, and ensure the net belt service life.

◆ Customized manufacturing is available.

◆ Low maintenance cost and simple to maintain.