PUR SUPER WIDTH LAMINATION MACHINE

The machine adopts solvent-free and environment-friendly hot-melt adhesive, which is suitable for 99% materials.we are the first domestic PUR manufacturer with PUR R&D history of 20 years in wide width PUR hot melt glue laminating machine which covered 95% domestic market (Haining,Keqiao etc).

We are a fabric lamination machine manufacturer with more than 25 years history.

We now own two plants:

1st plant Hongye machinery since 1998,

2nd plant Gaoqi machinery since 2015.

We are able to provide various solution about laminating,coating,embossing etc. In the past 25 years ,we accumulate much industry experience, many customers built up firm cooperation with us, under win-win business we growing up constantly. Welcome to consult us in depth details and visit us for more known about us!

Finished products have the following advantages:

Advantage:

◆ Solvent free,not toxicity,environmentally friendly

◆ Good adhesion and softness

◆ High and low temperature resistance

◆ Not easily affected by temperature after moisture reaction

◆ Breathable

◆ Wear resistance,oil resistance,aging resistance

◆ Light weight,softness

◆ Wash resistance

We provide customized machines with many years of experience, we are the first domestic PUR manufacturer with PUR R&D history of 20 years in wide width PUR hot melt glue laminating machine which covered 95% domestic market (Haining,Keqiao etc).

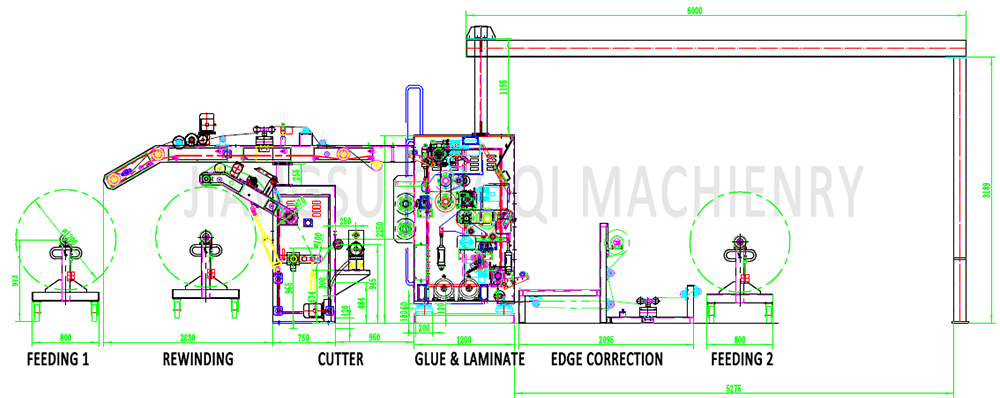

TECHNICAL DRAWING:(ONLY FOR REF)

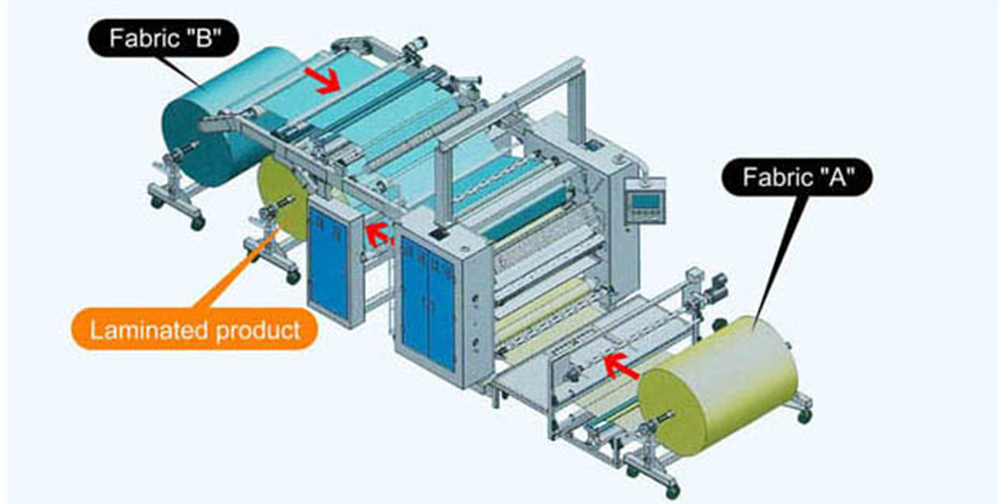

MACHINE PHOTO:

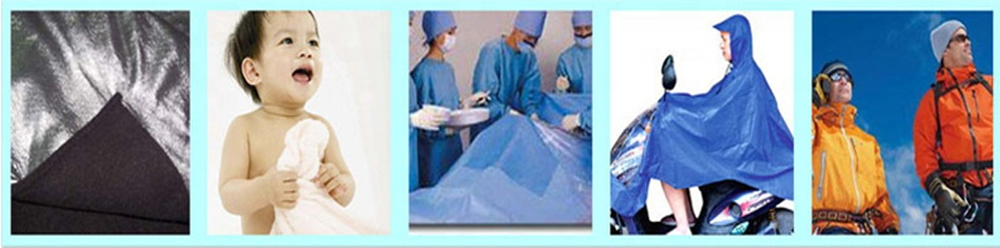

APPLICATION

It is suitable for 99.9% textiles, such as fabric + fabric, fabric + film, etc. It is widely used in clothing industry, automobile manufacturing industry, medical industry , environmental protection industry etc.

Application

◇ Regular apparels (fashion apparel,outerwear,etc.)

◇ Protection garments (industrial wear, medical wear, safety wear, etc.)

◇ Home textiles(mattress covers.baby bed protectors etc.)

◇ Inner wears(thermals,lingerie,etc.)

◇ Hygiene products(diapers.feminine hygiene products etc.)

◇ Defence garments,Sports apparel (sports gears,etc.), Filter material

◇ Medical industry

Suitable Material

◆ Fabric to fabric: textiles, jersey, fleece, Nylon, Velvet, Terry cloth, Suede, etc.

◆ Fabric to films: such as PU/TPU /PTFE /PE /PVC film, etc.

◆ Fabric to Leather/Artificial Leather, etc.

◆ Diving fabrics, Medical material, Non-woven products, Sponge/ Foam,Plastics,EVA+PVC,etc.

APPLICATION PHOTO:

MAIN TECHNICAL PARAMETERS:

|

SPECIFICATION |

GQ-2000-PUR /CUSTOMIZED |

|

MAX. PRODUCTION WIDTH: |

1800MM /CUSTOMIZED |

|

ROLLER SURFACE WIDTH: |

2000MM /CUSTOMIZED |

|

VOLTAGE: |

380V 50HZ 3P /CUSTOMIZED |

|

APPLICABLE GLUE: |

HOT MELT GLUE |

|

POWER: |

45KW |

|

DIMENSION(LXWXH) |

10500MMx3000MMx2700M |

|

OPERATION TYPE: |

PLC TOUCH SCREEN |

COMPONENT

The control adopts programmable PLC design and man-machine interface control, and the operation is simple. The tension-free feeding device is matched with the heating circulation system, which is convenient to control the temperature rise, temperature drop and stability of glue. The bonding materials and finished products can adopt Center / center winding or surface selection as required. The gluing methods are divided into dot gluing and mesh gluing.

WORKING PRINCIPLE

Our hot melt laminating machine is mainly consisted of fabric rewinding and unwinding units, fabric and film transmission systems and tension controller, film unwinding and lining or film carrier rewinding device, hot melt glue melting unit (optional), pump (optional), conduction oil source system (optional), glue dot transfer unit, laminating device, cooling device, PLC and other devices.